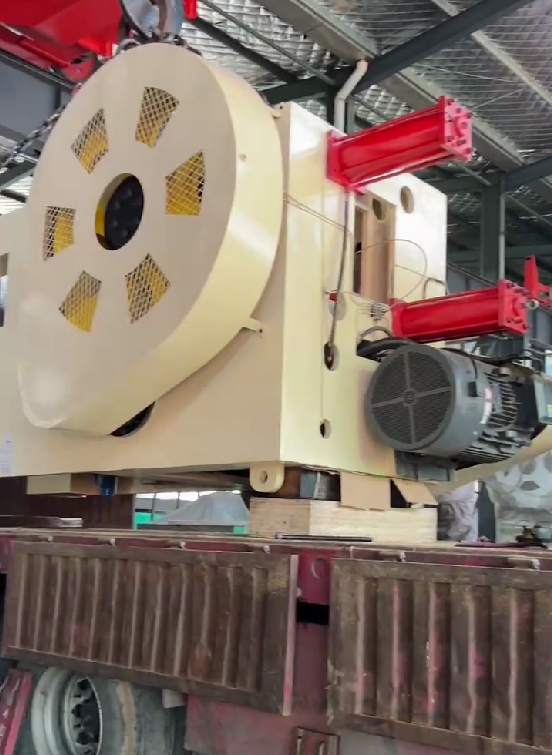

Hebei old customer repurchases two JH31 series

500 tons 200 tons hot forging presses, whole machine transportation

Hongfeng Machinery helps China's auto parts industry

The machine is equipped with special upper and lower material removal devices to meet the forging process requirements. Steel plate welding structure, tempered, strong rigidity, no deformation. Steel helical gears rotate, stable operation, low noise, not easy to damage teeth. Imported hydraulic overload protection device, safe and reliable to use. Once the car is stuck, it can be released by unscrewing the screw plug on the unloading valve to drain the oil in the cylinder, which is time-saving and convenient. The stroke speed is fast, which reduces the contact time between the forging and the die, thereby increasing the service life of the die and work efficiency. There is a feed port on the side of the fuselage, which is more convenient for the forging process. This press is an ideal model for the forging industry in recent years. It is mainly used for the hot forging process of small and medium-sized parts, and can also be used for the forging of connecting rods, gears, bearing rings and other parts.

|

|

English

English

Español

Español

Português

Português

русский

русский

français

français

日本語

日本語

Deutsch

Deutsch

Italiano

Italiano

Nederlands

Nederlands

ไทย

ไทย

Polski

Polski

한국어

한국어

Svenska

Svenska

magyar

magyar

Malay

Malay

বাংলা

বাংলা

Dansk

Dansk

Suomi

Suomi

Pilipino

Pilipino

Gaeilge

Gaeilge

عربى

عربى

norsk

norsk

اردو

اردو

čeština

čeština

Ελληνικά

Ελληνικά

Українська

Українська

فارسی

فارسی

नेपाली

नेपाली

български

български

ລາວ

ລາວ

Latine

Latine

Қазақ

Қазақ

Euskal

Euskal

Azərbaycan

Azərbaycan

slovenský

slovenský

Македонски

Македонски

Lietuvos

Lietuvos

Eesti Keel

Eesti Keel

Română

Română

Slovenski

Slovenski

मराठी

मराठी

Српски

Српски

Afrikaans

Afrikaans

Galego

Galego

Беларус

Беларус

Hrvatski

Hrvatski

Bosanski

Bosanski

Frysk

Frysk

Точик

Точик

O'zbek

O'zbek