-

English

English

-

Español

Español

-

Português

Português

-

русский

русский

-

français

français

-

日本語

日本語

-

Deutsch

Deutsch

-

Italiano

Italiano

-

Nederlands

Nederlands

-

ไทย

ไทย

-

Polski

Polski

-

한국어

한국어

-

Svenska

Svenska

-

magyar

magyar

-

Malay

Malay

-

বাংলা

বাংলা

-

Dansk

Dansk

-

Suomi

Suomi

-

Pilipino

Pilipino

-

Gaeilge

Gaeilge

-

عربى

عربى

-

norsk

norsk

-

اردو

اردو

-

čeština

čeština

-

Ελληνικά

Ελληνικά

-

Українська

Українська

-

فارسی

فارسی

-

नेपाली

नेपाली

-

български

български

-

ລາວ

ລາວ

-

Latine

Latine

-

Қазақ

Қазақ

-

Euskal

Euskal

-

Azərbaycan

Azərbaycan

-

slovenský

slovenský

-

Македонски

Македонски

-

Lietuvos

Lietuvos

-

Eesti Keel

Eesti Keel

-

Română

Română

-

Slovenski

Slovenski

-

मराठी

मराठी

-

Српски

Српски

-

Afrikaans

Afrikaans

-

Galego

Galego

-

Беларус

Беларус

-

Hrvatski

Hrvatski

-

Bosanski

Bosanski

-

Frysk

Frysk

-

Точик

Точик

-

O'zbek

O'zbek

Building Nail Hot Forging Machine

This machine uses advanced hot forging technology to forge metal materials into durable construction nails through plastic deformation at high temperatures.

Send Inquiry

Product Description

Hot Forging Machine

Product Content

This machine uses advanced hot forging technology to forge metal materials into durable construction nails through plastic deformation at high temperatures. The equipment integrates an efficient heating system, a precise forging mechanism and an intelligent control system to ensure that each construction nail can meet the best performance standards.

Technical Parameters

| Name | Unit | HFJ-260 | HFJ-400 | HFJ-650 | HFJ-850 | HFJ-1000 | HFJ-1250 | HFJ-2000 | |

| Nominal pressure | KN | 2600 | 4000 | 6500 | 8500 | 10000 | 12500 | 20000 | |

| Nominal force stroke | mm | 4 | 5 | 8 | 8 | 8 | 8 | 8 | |

| Slider stroke | mm | 120 | 180 | 180 | 180 | 160 | 250 | 180 | |

| Number of strokes | SPM | 40 | 32 | 30 | 30 | 30 | 25 | 22 | |

| Maximum die height | mm | 370 | 400 | 400 | 400 | 500 | 600 | 550 | |

| Die height adjustment | mm | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

| Column spacing | mm | 550 | 590 | 620 | 750 | 750 | 800 | 850 | |

| Work panel size | left and right | mm | 500 | 550 | 600 | 600 | 700 | 800 | 1000 |

| Before and after | 600 | 660 | 700 | 700 | 800 | 100 | 800 | ||

| Thick | 100 | 120 | 150 | 180 | 180 | 200 | 250 | ||

| Slider bottom dimensions | Left and right | mm | 400 | 400 | 450 | 450 | 480 | 800 | 800 |

| Front and back | 420 | 500 | 550 | 550 | 650 | 800 | 700 | ||

| Thickness | 80 | 90 | 90 | 95 | 100 | 120 | 120 | ||

| Die handle hole | ¢60 | ¢65 | ¢70 | ¢75 | ¢75 | ¢75 | ¢80 | ||

| Side opening size | Left and right | mm | 550 | 760 | 760 | 800 | 800 | 900 | 950 |

| Height | 650 | 700 | 780 | 850 | 850 | 950 | 1000 | ||

| Height of work surface from the ground (excluding height of shock-absorbing pads) | mm | 700 | 820±20 | 1000 | 1030 | 1300 | 1455 | 2030 | |

| Motor power | KW*P | 25*4 | 50*4 | 75*4 | 100*4 | 100*4 | 100*4 | 150*6 | |

| Air pressure | MPa | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | |

| Dimensions | Left and Right | mm | 2100 | 2640 | 3420 | 4980 | 4980 | 5060 | 6480 |

| Front and Back | 1955 | 2165 | 2460 | 2735 | 3160 | 3450 | 5470 | ||

| Thickness | 3850 | 4500 | 5060 | 5460 | 6234 | 7280 | 8000 | ||

Product Feature And Application

Efficient production: Automated production process greatly improves production efficiency, shortens production cycle, and meets the needs of large-scale construction projects.

Excellent quality: The high-temperature forging process gives construction nails excellent properties such as high strength, high toughness, and corrosion resistance, ensuring that they are still stable and reliable in various harsh environments.

Precise control: The advanced CNC system achieves precise control of key parameters such as temperature, pressure, and speed to ensure the dimensional accuracy and appearance quality of construction nails.

Various materials: Supports the forging of a variety of metal materials, including low-carbon steel, medium-carbon steel, stainless steel, etc., to meet the needs of different construction projects.

Strong durability: The equipment is made of high-quality materials, with a sturdy and durable structure, which can withstand the load of long-term continuous work and reduce maintenance costs.

Widely used in various fields of the construction industry, such as residential construction, commercial buildings, infrastructure projects, etc., to provide strong connections and support for various building structures.

Product Details

The cold-warm extruder used in cold-warm extrusion can be single-station or multi-station; the multi-station cold-warm extruder has the functions of cold-warm extruder and multi-station press at the same time, with the advantages of small footprint and high production efficiency, which is very suitable for mass production.

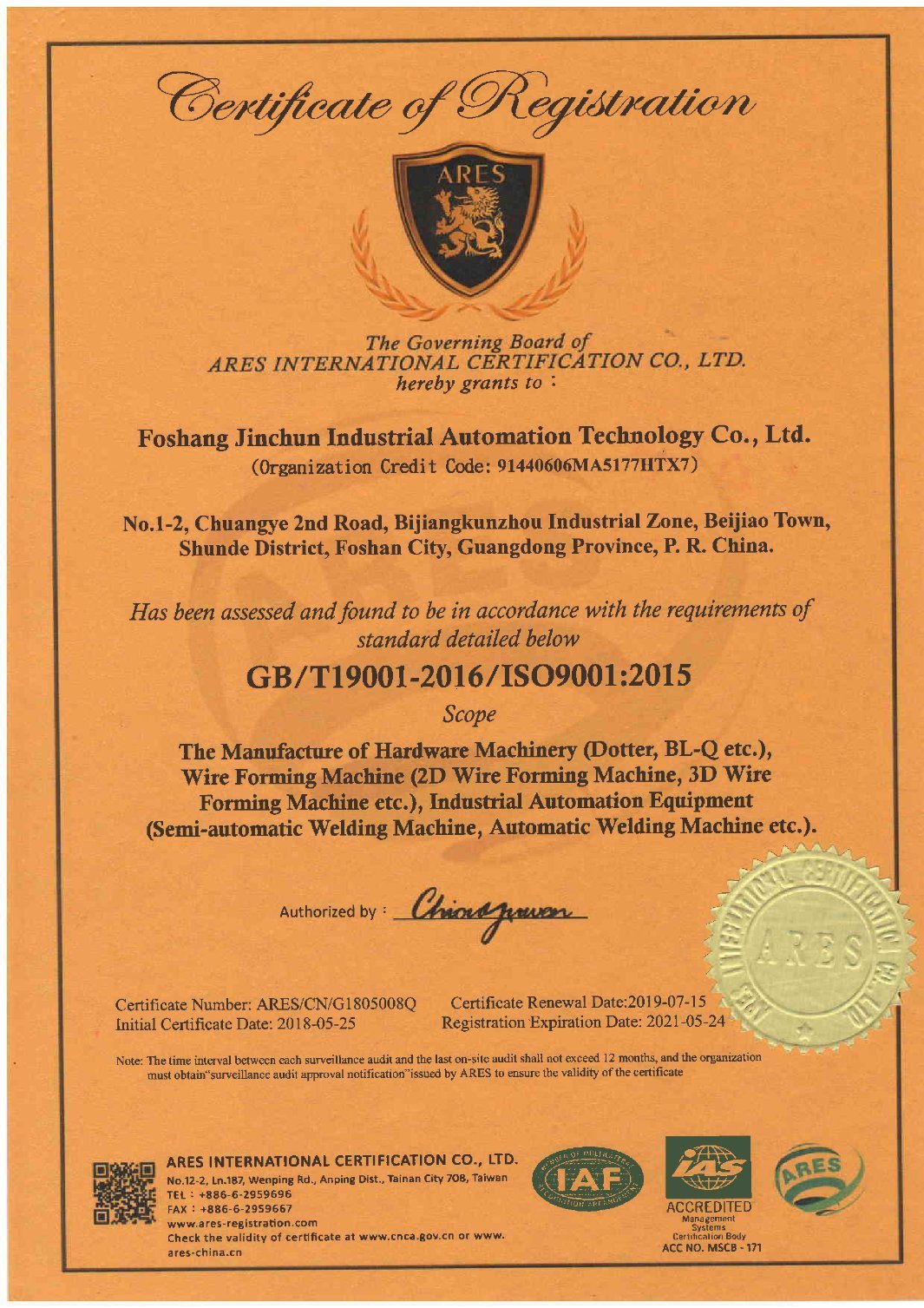

5. Product Qualification

|

|

6. Deliver, Shipping And Serving of Delivery, Transportation and Services

The transportation period must be linked to the delivery date, and the transportation time limit should be guaranteed. Choose the transportation tool according to the transportation time. Generally, it is transported by truck, ship, and container.

|

|

FAQ

Q:Can you send your staff to set up the equipment for us?

A:Agreed. Round-trip tickets and accommodation for technicians are to be borne or arranged by the Buyer.

Q:Can I just buy some spare parts from you?

A:Yes, please contact us for more information.

Q:Will you attend the exhibition?

A:Yes, I have attended many exhibitions.

Q:How long has your company been making this kind of equipment?

A:Our company has more than 20 years of production history, is a professional manufacturer of hot forging equipment.

Q:What certificates do you have for your device?

A:Our equipment has CE certification, safety production standardization certificate, enterprise credit certificate, China machinery industry credit certificate, heavy quality credit enterprise certificate, quality service integrity enterprise certificate, a clamping overload protector patent certificate, a stopper component patent certificate, a fine-tuning gripper patent certificate, a double cooling brake patent certificate, a tap type slide special Interest certificate, a forging slag removal device patent certificate and other certificates.

Q:How many employees do you have in your factory?

A:More than 20 people.

Q:Where is your factory?

A:Our factory is in Gao Mi City, Wei Fang City, Shandong Province, China.

Company Introduction

Shandong Gaomi Hongfeng Machinery Co., Ltd. is located in Gaomi City, the hometown of Mo Yan. It is adjacent to the famous tourist city Qingdao in the east and the world's kite capital Weifang in the west. The Jiqing High-speed Railway Expressway runs across the east and west. It is less than 40 kilometers away from Qingdao Jiaodong International Airport. It has a superior geographical environment and smooth transportation.

Gaomi Hongfeng Machinery Co., Ltd. has a production history of more than 20 years. It is a professional manufacturer of hot forging equipment. With many years of experience and professional knowledge, it is committed to providing customers with high-quality forging products and services. The company mainly produces more than 70 varieties of eight series, including HK, HK, DH10, JH31, HFP, HFZ, HFJ, and JH21. The products cover multiple fields such as automobiles, aviation, rail transit, petrochemicals, and electricity. It is a supplier of many well-known companies.

We have advanced forging equipment and technology, which can meet customers' needs for high-precision and high-quality products. Our team is composed of senior engineers and technicians, and can provide a full range of technical support and solutions. We focus on quality management and pass the IS09001 quality management system certification to ensure the stability and reliability of product quality.

We are well aware of customers' requirements for delivery time, and we can quickly respond to customer needs to provide accurate delivery time and fast logistics services. Our sales and service teams always maintain good communication and feedback to ensure the continuous improvement of customer satisfaction.

Our company has always adhered to the principles of customer-centricity, pursuit of excellence, and honest operation, and continuously improved its own technology and service level to create greater value for customers. Friends from all walks of life are welcome to come to discuss business and create a better future.